Data Scientists & Full Stack Developers

D3S:

Data Science Softwares & Services.

Our team, composed of Data Scientists and Full Stack Developers, designs software solutions leveraging the most advanced artificial intelligence technologies.

We work on high-value projects that combine business complexity, large data volumes, and industrial constraints.

Our engineers and PhDs, trained at top-tier institutions, bring together strong applied mathematics expertise, mastery of AI models, and rigorous software development skills.

D3S, AI and Data Science expertise

Sébastien podetti

Founder of D3S

Since 2016, STEP and Sébastien Podetti shared a common conviction: the immense potential of combining massive enterprise data with the power of algorithms.

This vision led to the creation of D3S – Data Science Softwares & Services, alongside Louis Gautier de La Plaine and a team of experts in applied mathematics and software development.

Since its inception, D3S has been designing innovative solutions to transform the potential of industrial data into tangible performance levers.

Louis Gautier de La Plaine

Data Science & AI Project Manager

Our technology modules

Cutting-edge tools, deployable quickly, and already proven with our clients.

Our team develops high-performance in-house technologies capable of addressing complex use cases with speed and reliability. These software blocks form the backbone of our custom solutions, continuously evolving through our R&D efforts.

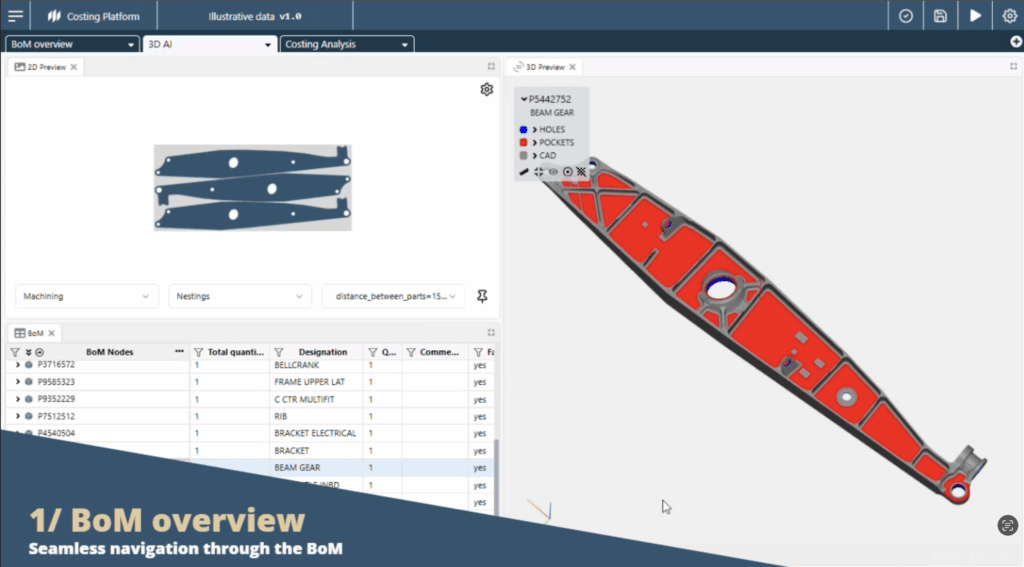

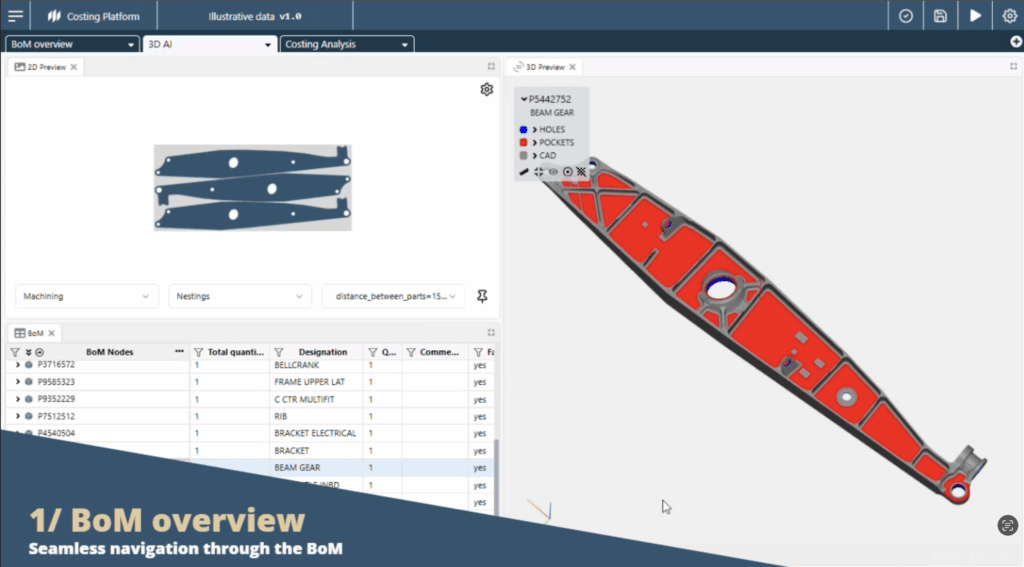

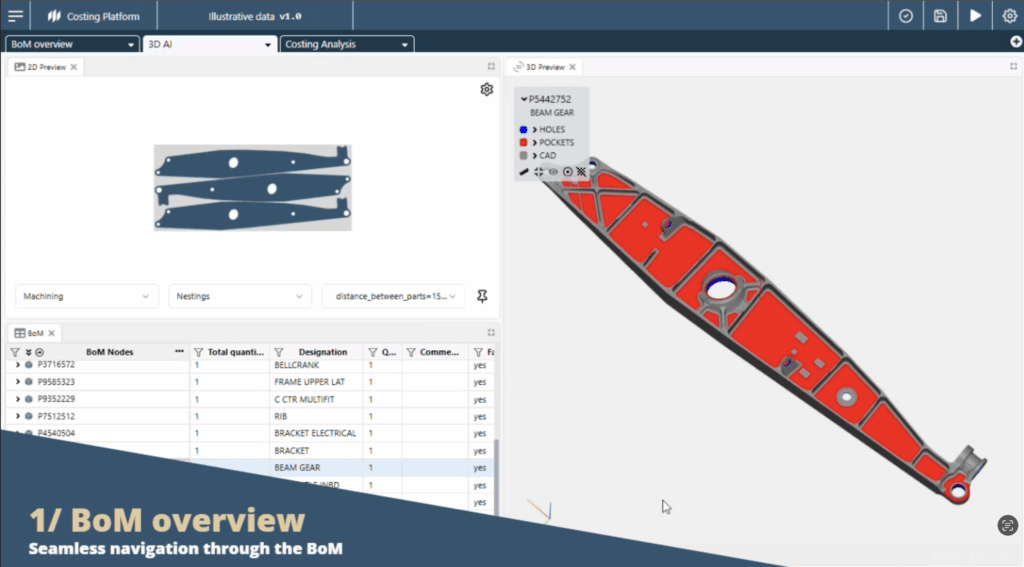

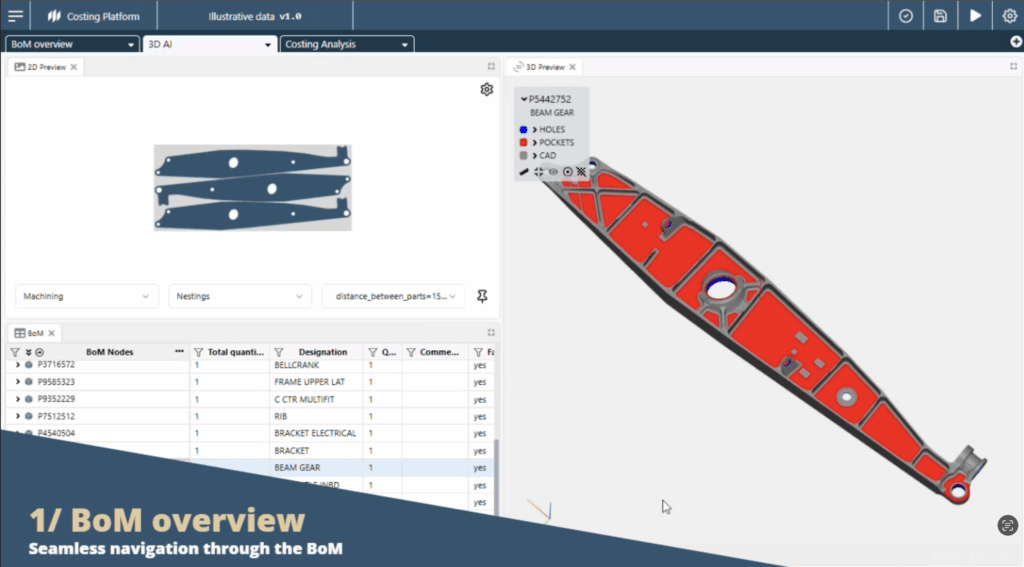

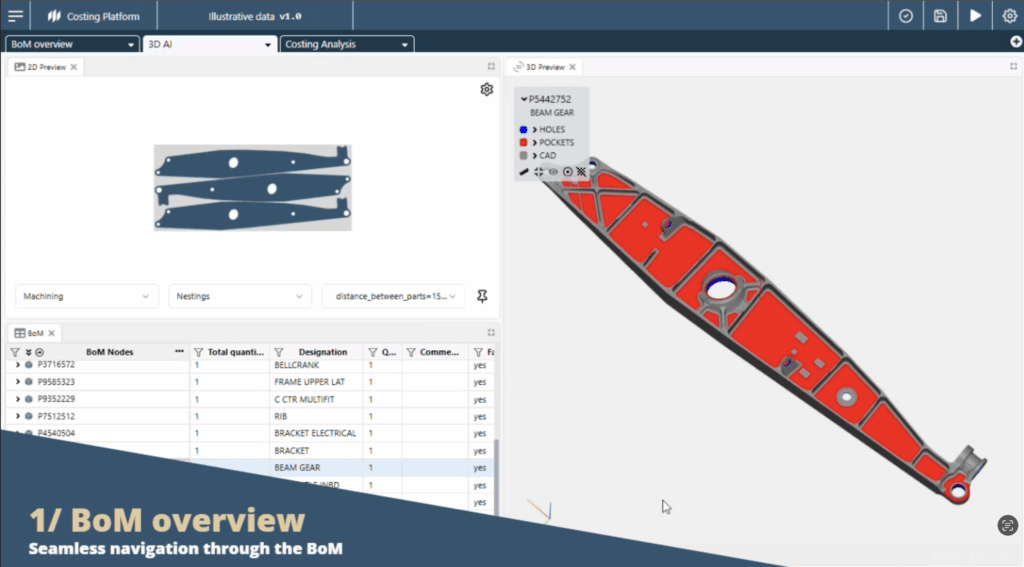

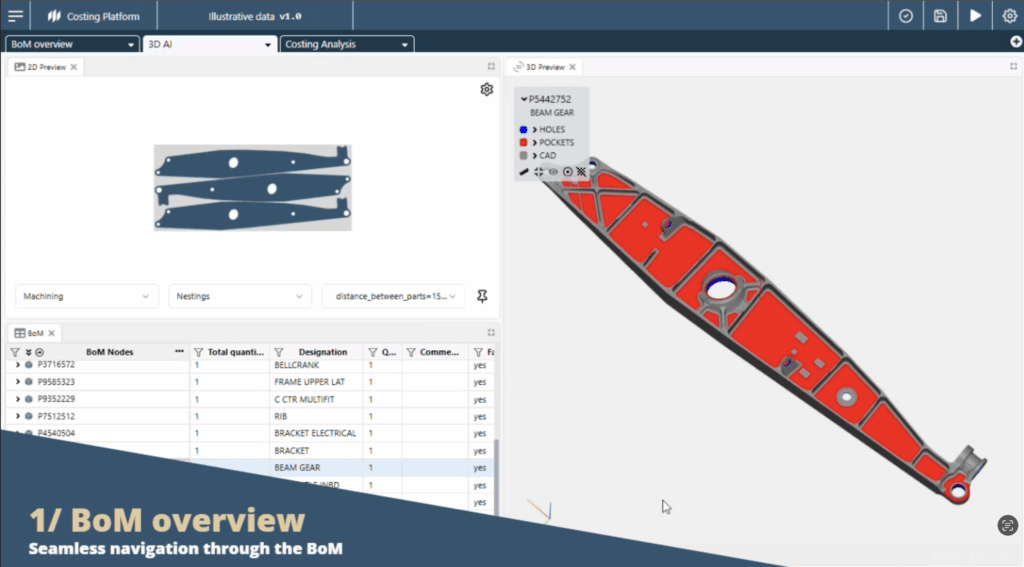

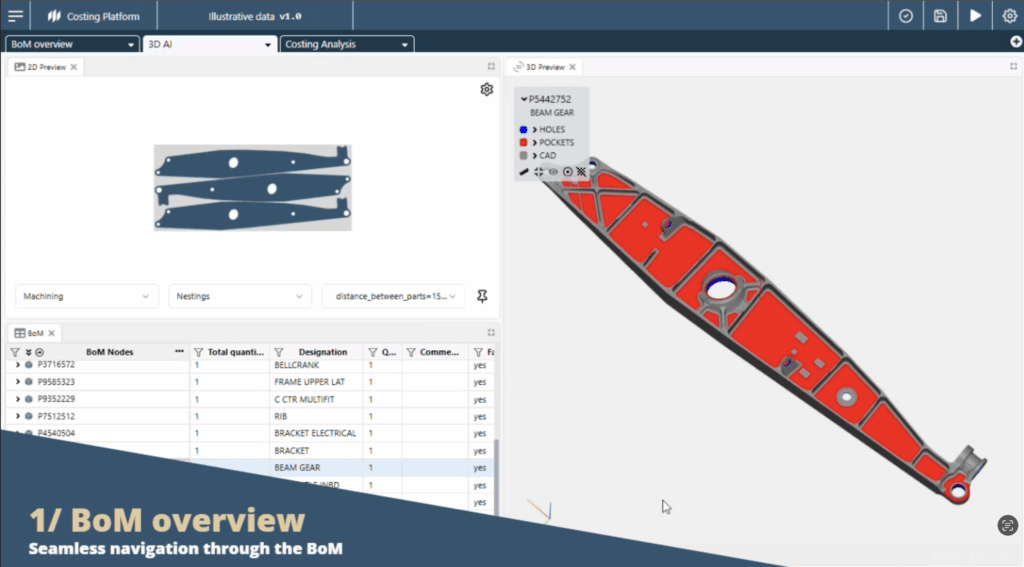

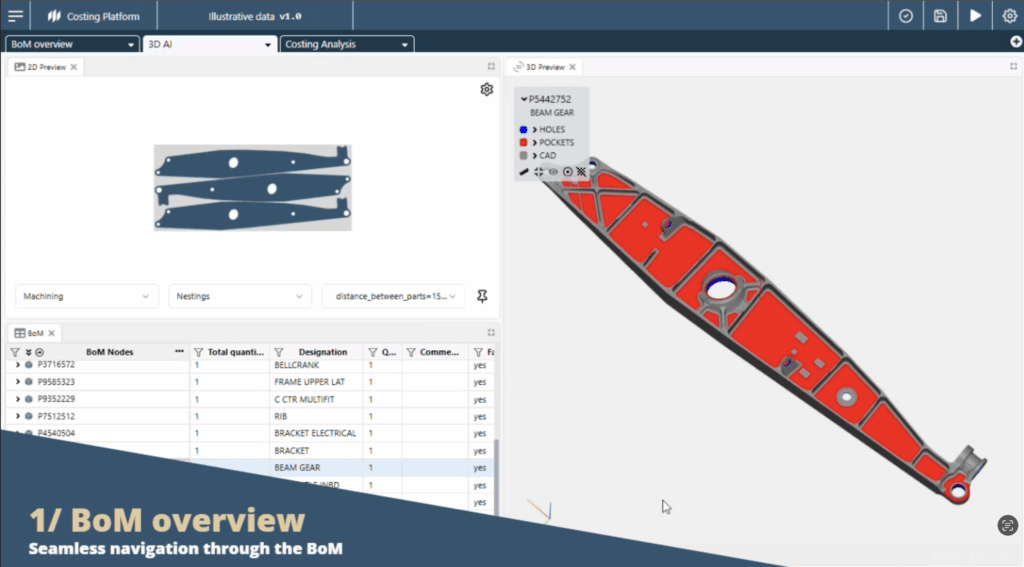

Blacksmith, 3D AI

Analyze Your 3D Data at Scale with AI

We have developed an advanced morphological analysis technology for complex products (aerospace, automotive, etc.). Optimized for large-scale data processing, this tool enables:

- Automatic identification of similarities across thousands of components

- 3D parts categorization

- Extraction of cost drivers related to manufacturing processes (machining, sheet metal, composites, etc.)

Continuously evolving, we are already working on the next-generation version.

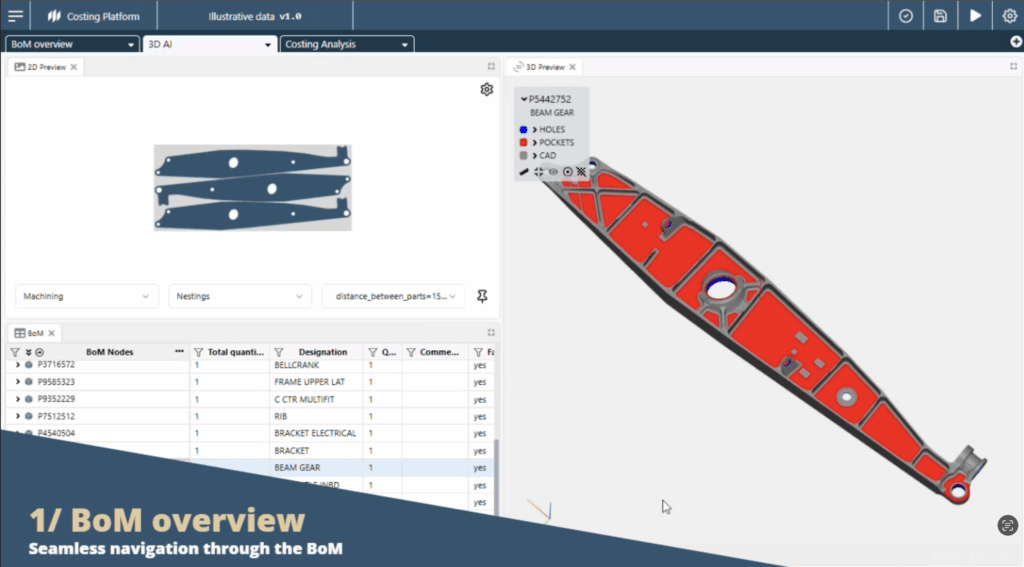

Estimate Your Product Costs, Even the Most Complex Ones

Our platform allows you to estimate the costs of thousands of parts using our proprietary algorithms, designed for the demands of complex industrial environments (aerospace, automotive, etc.). It is highly configurable to adapt to each client’s specific needs, including:

- Heterogeneous data formats and sources

- Management of cost models and internal reference data

- Custom reporting and business insights requirements

Its modular architecture enables rapid integration and scalable deployment:

- Ergonomic web front-end, customizable to user workflows

- Scalable database, built for large volumes

- Robust back-end, integrating our estimation and AI engines

- Highly customizable cost models, designed in low-code mode

From Idea to MVP in Record Time

We have developed a rapid prototyping platform to efficiently transform an idea into operational software. Built on reusable modular components, it enables :

- Storage and processing of large-scale data

- Creation of custom user interfaces

- Integration of advanced analytics and visualization modules

Ideal for quickly building custom software designed to automate and optimize even the most complex business processes.

Digital Costing Software

Analyze Your 3D Data at Scale with AI

We have developed an advanced morphological analysis technology for complex products (aerospace, automotive, etc.). Optimized for large-scale data processing, this tool enables:

- Automatic identification of similarities across thousands of components

- 3D parts categorization

- Extraction of cost drivers related to manufacturing processes (machining, sheet metal, composites, etc.)

Continuously evolving, we are already working on the next-generation version.

Estimate Your Product Costs, Even the Most Complex Ones

Our platform allows you to estimate the costs of thousands of parts using our proprietary algorithms, designed for the demands of complex industrial environments (aerospace, automotive, etc.). It is highly configurable to adapt to each client’s specific needs, including:

- Heterogeneous data formats and sources

- Management of cost models and internal reference data

- Custom reporting and business insights requirements

Its modular architecture enables rapid integration and scalable deployment:

- Ergonomic web front-end, customizable to user workflows

- Scalable database, built for large volumes

- Robust back-end, integrating our estimation and AI engines

- Highly customizable cost models, designed in low-code mode

From Idea to MVP in Record Time

We have developed a rapid prototyping platform to efficiently transform an idea into operational software. Built on reusable modular components, it enables :

- Storage and processing of large-scale data

- Creation of custom user interfaces

- Integration of advanced analytics and visualization modules

Ideal for quickly building custom software designed to automate and optimize even the most complex business processes.

Fast Prototyping platform

Analyze Your 3D Data at Scale with AI

We have developed an advanced morphological analysis technology for complex products (aerospace, automotive, etc.). Optimized for large-scale data processing, this tool enables:

- Automatic identification of similarities across thousands of components

- 3D parts categorization

- Extraction of cost drivers related to manufacturing processes (machining, sheet metal, composites, etc.)

Continuously evolving, we are already working on the next-generation version.

Estimate Your Product Costs, Even the Most Complex Ones

Our platform allows you to estimate the costs of thousands of parts using our proprietary algorithms, designed for the demands of complex industrial environments (aerospace, automotive, etc.). It is highly configurable to adapt to each client’s specific needs, including:

- Heterogeneous data formats and sources

- Management of cost models and internal reference data

- Custom reporting and business insights requirements

Its modular architecture enables rapid integration and scalable deployment:

- Ergonomic web front-end, customizable to user workflows

- Scalable database, built for large volumes

- Robust back-end, integrating our estimation and AI engines

- Highly customizable cost models, designed in low-code mode

From Idea to MVP in Record Time

We have developed a rapid prototyping platform to efficiently transform an idea into operational software. Built on reusable modular components, it enables :

- Storage and processing of large-scale data

- Creation of custom user interfaces

- Integration of advanced analytics and visualization modules

Ideal for quickly building custom software designed to automate and optimize even the most complex business processes.

Analyze Your 3D Data at Scale with AI

We have developed an advanced morphological analysis technology for complex products (aerospace, automotive, etc.). Optimized for large-scale data processing, this tool enables:

- Automatic identification of similarities across thousands of components

- 3D parts categorization

- Extraction of cost drivers related to manufacturing processes (machining, sheet metal, composites, etc.)

Continuously evolving, we are already working on the next-generation version.

Estimate Your Product Costs, Even the Most Complex Ones

Our platform allows you to estimate the costs of thousands of parts using our proprietary algorithms, designed for the demands of complex industrial environments (aerospace, automotive, etc.). It is highly configurable to adapt to each client’s specific needs, including:

- Heterogeneous data formats and sources

- Management of cost models and internal reference data

- Custom reporting and business insights requirements

Its modular architecture enables rapid integration and scalable deployment:

- Ergonomic web front-end, customizable to user workflows

- Scalable database, built for large volumes

- Robust back-end, integrating our estimation and AI engines

- Highly customizable cost models, designed in low-code mode

From Idea to MVP in Record Time

We have developed a rapid prototyping platform to efficiently transform an idea into operational software. Built on reusable modular components, it enables :

- Storage and processing of large-scale data

- Creation of custom user interfaces

- Integration of advanced analytics and visualization modules

Ideal for quickly building custom software designed to automate and optimize even the most complex business processes.

Our expertises

Cutting-edge technologies, mastered and enhanced by our internal R&D.

Our team leverages the best open-source libraries while developing proprietary methods in our lab. This dual approach allows us to tackle complex industrial challenges effectively, combining scientific rigor, performance, and agility.

Gen AI & Agentic AI

AI empowering operations

We leverage generative and agent-based AI to go beyond traditional data processing approaches. Our work focuses on three main areas:

- Analysis of unstructured data (PDFs, free text, technical diagrams, etc.)

- Automation of complex data processing tasks

Adding intelligent layers to our software solutions to facilitate:

- Result analysis

- Model creation or adjustment

- Navigation in rich or technical environments

These AI capabilities also enhance our internal processes, accelerating development cycles. With AI assistants, our data scientists and developers become more efficient and creative, delivering high-performance solutions quickly.

Optimizing Operations with Algorithms

We master reinforcement learning and genetic algorithms to solve complex problems, often under tight constraints. Our main areas of application include:

- Logistics flow optimization: reducing transit times and improving service levels

- Industrial planning and engineering: building robust schedules that adapt to uncertainties and available resources

- Material nesting optimization: minimizing waste and improving cutting yields

These algorithms automate the search for optimal solutions and enable rapid exploration of high-impact alternative scenarios.

Neural Networks for Complex, Unstructured Data

We deploy deep learning architectures whenever the complexity, variety, or volume of data requires it. Our dedicated internal infrastructure allows us to efficiently train demanding models while maintaining full control over our processes. Key use cases include:

- Vision par ordinateur : extraction de caractéristiques techniques depuis des images ou documents (PDF, CAO, etc.),

- Séries temporelles : prévisions (forecast) sur des données industrielles ou opérationnelles,

- Classification et segmentation : identification de patterns d’inefficience pour orienter les actions d’amélioration.

Ces approches robustes nous permettent d’adresser des problématiques industrielles avec précision et efficacité.

- Computer vision: extracting technical features from images or documents (PDFs, CAD, etc.)

- Time series: forecasting industrial or operational data

- Classification and segmentation: identifying inefficiency patterns to guide improvement actions

These robust approaches enable us to tackle industrial challenges with precision and efficiency.

Structuring and Modeling Raw Data to Support Reliable Decisions

We process large volumes of data directly extracted from source systems (ERP, PLM, etc.) to structure, enrich, and transform them into operational models. Our work focuses on:

- Financial projection of costs for financial control and competitiveness projects

- Modeling stock dynamics to anticipate part shortages

- Cross-analysis of production, supply chain, and performance data to support objective decision-making

By combining statistical methods, business modeling, and interactive visualizations, we build robust tools designed to guide action at all levels of the organization.er l’action à tous les niveaux de l’organisation.

RL & Optimization

AI empowering operations

We leverage generative and agent-based AI to go beyond traditional data processing approaches. Our work focuses on three main areas:

- Analysis of unstructured data (PDFs, free text, technical diagrams, etc.)

- Automation of complex data processing tasks

Adding intelligent layers to our software solutions to facilitate:

- Result analysis

- Model creation or adjustment

- Navigation in rich or technical environments

These AI capabilities also enhance our internal processes, accelerating development cycles. With AI assistants, our data scientists and developers become more efficient and creative, delivering high-performance solutions quickly.

Optimizing Operations with Algorithms

We master reinforcement learning and genetic algorithms to solve complex problems, often under tight constraints. Our main areas of application include:

- Logistics flow optimization: reducing transit times and improving service levels

- Industrial planning and engineering: building robust schedules that adapt to uncertainties and available resources

- Material nesting optimization: minimizing waste and improving cutting yields

These algorithms automate the search for optimal solutions and enable rapid exploration of high-impact alternative scenarios.

Neural Networks for Complex, Unstructured Data

We deploy deep learning architectures whenever the complexity, variety, or volume of data requires it. Our dedicated internal infrastructure allows us to efficiently train demanding models while maintaining full control over our processes. Key use cases include:

- Vision par ordinateur : extraction de caractéristiques techniques depuis des images ou documents (PDF, CAO, etc.),

- Séries temporelles : prévisions (forecast) sur des données industrielles ou opérationnelles,

- Classification et segmentation : identification de patterns d’inefficience pour orienter les actions d’amélioration.

Ces approches robustes nous permettent d’adresser des problématiques industrielles avec précision et efficacité.

- Computer vision: extracting technical features from images or documents (PDFs, CAD, etc.)

- Time series: forecasting industrial or operational data

- Classification and segmentation: identifying inefficiency patterns to guide improvement actions

These robust approaches enable us to tackle industrial challenges with precision and efficiency.

Structuring and Modeling Raw Data to Support Reliable Decisions

We process large volumes of data directly extracted from source systems (ERP, PLM, etc.) to structure, enrich, and transform them into operational models. Our work focuses on:

- Financial projection of costs for financial control and competitiveness projects

- Modeling stock dynamics to anticipate part shortages

- Cross-analysis of production, supply chain, and performance data to support objective decision-making

By combining statistical methods, business modeling, and interactive visualizations, we build robust tools designed to guide action at all levels of the organization.er l’action à tous les niveaux de l’organisation.

Deep learning

AI empowering operations

We leverage generative and agent-based AI to go beyond traditional data processing approaches. Our work focuses on three main areas:

- Analysis of unstructured data (PDFs, free text, technical diagrams, etc.)

- Automation of complex data processing tasks

Adding intelligent layers to our software solutions to facilitate:

- Result analysis

- Model creation or adjustment

- Navigation in rich or technical environments

These AI capabilities also enhance our internal processes, accelerating development cycles. With AI assistants, our data scientists and developers become more efficient and creative, delivering high-performance solutions quickly.

Optimizing Operations with Algorithms

We master reinforcement learning and genetic algorithms to solve complex problems, often under tight constraints. Our main areas of application include:

- Logistics flow optimization: reducing transit times and improving service levels

- Industrial planning and engineering: building robust schedules that adapt to uncertainties and available resources

- Material nesting optimization: minimizing waste and improving cutting yields

These algorithms automate the search for optimal solutions and enable rapid exploration of high-impact alternative scenarios.

Neural Networks for Complex, Unstructured Data

We deploy deep learning architectures whenever the complexity, variety, or volume of data requires it. Our dedicated internal infrastructure allows us to efficiently train demanding models while maintaining full control over our processes. Key use cases include:

- Vision par ordinateur : extraction de caractéristiques techniques depuis des images ou documents (PDF, CAO, etc.),

- Séries temporelles : prévisions (forecast) sur des données industrielles ou opérationnelles,

- Classification et segmentation : identification de patterns d’inefficience pour orienter les actions d’amélioration.

Ces approches robustes nous permettent d’adresser des problématiques industrielles avec précision et efficacité.

- Computer vision: extracting technical features from images or documents (PDFs, CAD, etc.)

- Time series: forecasting industrial or operational data

- Classification and segmentation: identifying inefficiency patterns to guide improvement actions

These robust approaches enable us to tackle industrial challenges with precision and efficiency.

Structuring and Modeling Raw Data to Support Reliable Decisions

We process large volumes of data directly extracted from source systems (ERP, PLM, etc.) to structure, enrich, and transform them into operational models. Our work focuses on:

- Financial projection of costs for financial control and competitiveness projects

- Modeling stock dynamics to anticipate part shortages

- Cross-analysis of production, supply chain, and performance data to support objective decision-making

By combining statistical methods, business modeling, and interactive visualizations, we build robust tools designed to guide action at all levels of the organization.er l’action à tous les niveaux de l’organisation.

Mass modeling

AI empowering operations

We leverage generative and agent-based AI to go beyond traditional data processing approaches. Our work focuses on three main areas:

- Analysis of unstructured data (PDFs, free text, technical diagrams, etc.)

- Automation of complex data processing tasks

Adding intelligent layers to our software solutions to facilitate:

- Result analysis

- Model creation or adjustment

- Navigation in rich or technical environments

These AI capabilities also enhance our internal processes, accelerating development cycles. With AI assistants, our data scientists and developers become more efficient and creative, delivering high-performance solutions quickly.

Optimizing Operations with Algorithms

We master reinforcement learning and genetic algorithms to solve complex problems, often under tight constraints. Our main areas of application include:

- Logistics flow optimization: reducing transit times and improving service levels

- Industrial planning and engineering: building robust schedules that adapt to uncertainties and available resources

- Material nesting optimization: minimizing waste and improving cutting yields

These algorithms automate the search for optimal solutions and enable rapid exploration of high-impact alternative scenarios.

Neural Networks for Complex, Unstructured Data

We deploy deep learning architectures whenever the complexity, variety, or volume of data requires it. Our dedicated internal infrastructure allows us to efficiently train demanding models while maintaining full control over our processes. Key use cases include:

- Vision par ordinateur : extraction de caractéristiques techniques depuis des images ou documents (PDF, CAO, etc.),

- Séries temporelles : prévisions (forecast) sur des données industrielles ou opérationnelles,

- Classification et segmentation : identification de patterns d’inefficience pour orienter les actions d’amélioration.

Ces approches robustes nous permettent d’adresser des problématiques industrielles avec précision et efficacité.

- Computer vision: extracting technical features from images or documents (PDFs, CAD, etc.)

- Time series: forecasting industrial or operational data

- Classification and segmentation: identifying inefficiency patterns to guide improvement actions

These robust approaches enable us to tackle industrial challenges with precision and efficiency.

Structuring and Modeling Raw Data to Support Reliable Decisions

We process large volumes of data directly extracted from source systems (ERP, PLM, etc.) to structure, enrich, and transform them into operational models. Our work focuses on:

- Financial projection of costs for financial control and competitiveness projects

- Modeling stock dynamics to anticipate part shortages

- Cross-analysis of production, supply chain, and performance data to support objective decision-making

By combining statistical methods, business modeling, and interactive visualizations, we build robust tools designed to guide action at all levels of the organization.er l’action à tous les niveaux de l’organisation.

AI empowering operations

We leverage generative and agent-based AI to go beyond traditional data processing approaches. Our work focuses on three main areas:

- Analysis of unstructured data (PDFs, free text, technical diagrams, etc.)

- Automation of complex data processing tasks

Adding intelligent layers to our software solutions to facilitate:

- Result analysis

- Model creation or adjustment

- Navigation in rich or technical environments

These AI capabilities also enhance our internal processes, accelerating development cycles. With AI assistants, our data scientists and developers become more efficient and creative, delivering high-performance solutions quickly.

Optimizing Operations with Algorithms

We master reinforcement learning and genetic algorithms to solve complex problems, often under tight constraints. Our main areas of application include:

- Logistics flow optimization: reducing transit times and improving service levels

- Industrial planning and engineering: building robust schedules that adapt to uncertainties and available resources

- Material nesting optimization: minimizing waste and improving cutting yields

These algorithms automate the search for optimal solutions and enable rapid exploration of high-impact alternative scenarios.

Neural Networks for Complex, Unstructured Data

We deploy deep learning architectures whenever the complexity, variety, or volume of data requires it. Our dedicated internal infrastructure allows us to efficiently train demanding models while maintaining full control over our processes. Key use cases include:

- Vision par ordinateur : extraction de caractéristiques techniques depuis des images ou documents (PDF, CAO, etc.),

- Séries temporelles : prévisions (forecast) sur des données industrielles ou opérationnelles,

- Classification et segmentation : identification de patterns d’inefficience pour orienter les actions d’amélioration.

Ces approches robustes nous permettent d’adresser des problématiques industrielles avec précision et efficacité.

- Computer vision: extracting technical features from images or documents (PDFs, CAD, etc.)

- Time series: forecasting industrial or operational data

- Classification and segmentation: identifying inefficiency patterns to guide improvement actions

These robust approaches enable us to tackle industrial challenges with precision and efficiency.

Structuring and Modeling Raw Data to Support Reliable Decisions

We process large volumes of data directly extracted from source systems (ERP, PLM, etc.) to structure, enrich, and transform them into operational models. Our work focuses on:

- Financial projection of costs for financial control and competitiveness projects

- Modeling stock dynamics to anticipate part shortages

- Cross-analysis of production, supply chain, and performance data to support objective decision-making

By combining statistical methods, business modeling, and interactive visualizations, we build robust tools designed to guide action at all levels of the organization.er l’action à tous les niveaux de l’organisation.

Our Success stories

Explore our expertise through our most impactful success stories.

Engineering

Sourcing

Supply Chain

Logistics

Production

Finance

After Sales

Corporate

Data

Driving Competitiveness

D3S expertise amplifies STEP’s impact on clients’ competitiveness by turning data into tangible performance levers through the development of innovative solutions.

Founder of D3S

Founder of D3S – Expert in Artificial Intelligence and Digital Transformation

Sébastien Podetti

A SUPAERO graduate, Sébastien brings 20 years of experience leading projects with strong analytics. He has designed and deployed numerous performance improvement solutions across corporate functions: Finance, Procurement, Engineering, Quality, Supply Chain, Logistics, and more.

From defining data/AI roadmaps to designing and delivering custom software platforms, he supports industrial clients in their analytical transformation by combining strategic vision, technical expertise, and hands-on operational approach.

Data Science & AI Project Manager

Technical Expert and Full Stack Leader

Louis Gautier de La Plaine

A graduate of Centrale Paris (Centrale Supélec), Louis has 9 years of experience in data science, artificial intelligence, and software engineering.

An expert across a broad spectrum of advanced algorithms (machine learning, deep learning, optimization), he combines scientific rigor with software architecture mastery to design robust, scalable solutions.

As a Full Stack Manager, he leads the development of our AI technologies and oversees the team responsible for our 3D data analysis algorithms.